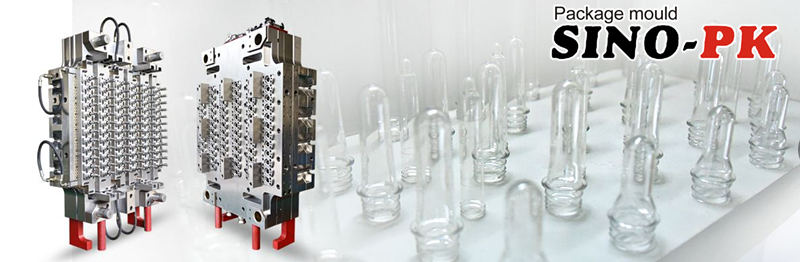

SINO PK is specialized in making PET preform molds, plastic cap mould and other package mould in China area. We have exported many high quality package moulds in the past years.

elow is some common problem which will happen in the PET preform mould, and also some solution for PET preform mould.

Problem 1:

Usually, the big problem will happen to the PET preform mould hot runner system.

Sometimes, customer will find that after several months running, material will not come out from the hot tip. Or some cavities could not be fully filled.

If happen this problem, firstly customer should open the mould and check whether there is something stuck in the hot runner that causing the hot sip stuck. To do some cleaning works may solve this problem. If the problem is serious, customer should contact with hot runner supplier.

Problem 2:

PET preform mould screw become loose

We suggest every one week, customer need to check all the mould screw and fasten them regularly.

Problem 3:

Product yellowing

This problem could be solved by adjusting the PET preform mould hot runner temperature. Especially, the hot tip temperature.

Problem 4:

Product opacification

One solution is to dry the PET material and plastic mold material much better.

Another is checking the cooling system, ensure the cooling effect is reach the best.|

reputable PET preform mould manufacturer,making high quality PET preform mould,Husky PET preform mould competitor,how to find good PET preform mould supplier,superior quality PET preform mold in China